What Makes Them Stand Out?

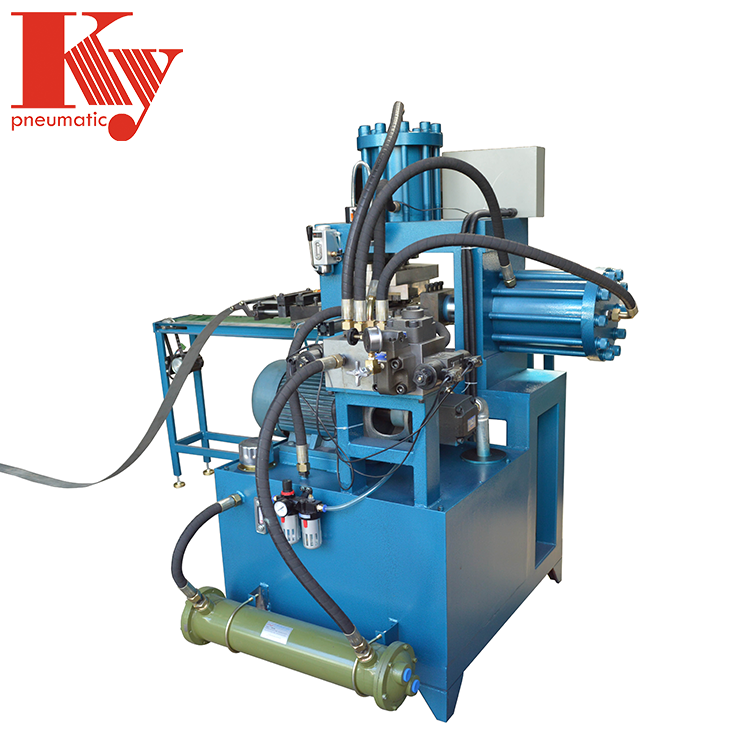

One of the best things about KY's pneumatic nail machines is their power. They use compressed air to drive nails into surfaces. This means they work faster than manual tools. Imagine trying to hammer nails by hand versus using a nail gun. The nail gun saves time and effort, which is great for busy workers. Another standout feature is the customization options. Users can select different nail sizes and types based on what they are working on. For example, if you are making a delicate piece of furniture, you might choose smaller nails. But if you are building a sturdy wooden deck, larger nails are better. This flexibility makes KY machines suitable for various projects. Additionally, the design of these machines is user-friendly. They are lightweight, which makes them easy to carry around. The trigger mechanism is designed to be smooth and responsive, allowing for precise control. This is important for both safety and accuracy. Workers can feel confident when using our machines, knowing they won’t misfire easily. Moreover, KY’s pneumatic nail machines are made with high-quality materials. This means they can withstand tough working conditions, whether it’s in a hot, dusty environment or a cold, wet one. Maintenance is easy too. Most machines have parts that can be replaced or repaired, which extends their lifespan. Overall, KY combines functionality, durability, and user-friendliness in our pneumatic nail machines, making them a favorite among professionals.

What Are the Common Usage Issues with Pneumatic Nail Machines?

Even with great machines like those from KY, users sometimes face challenges. One common issue is jams. A jam happens when the nails get stuck inside the machine. This can be frustrating, especially if you are in the middle of a project. It slows down work and can lead to wasted time. Jams often occur if the wrong type of nails is used or if the machine isn’t loaded correctly. To avoid this, workers should always check the specifications and make sure they are using the right nails for their machine. Another problem is air leaks. If there’s a leak in the air hose or connections, the Pin Nail Making Machine may not work efficiently. This can result in weak nail drives or missed nails altogether. Regularly checking connections and maintaining hoses can help prevent this issue. Additionally, operators sometimes struggle with the pressure settings. If the pressure is too low, nails might not go in all the way. If it’s too high, nails can go in too deep or even damage the material. Finding the right pressure takes some practice but is vital for perfect results. Safety is also a concern. Sometimes users forget to wear protective gear, like goggles or gloves. This can lead to accidents, especially if the machine misfires. It’s important for everyone to follow safety guidelines when using powerful tools like pneumatic nail machines. Finally, not cleaning the machines regularly can lead to dirt buildup, which impacts performance. Taking care of the machines means they will last longer and work better, ensuring that every project turns out great. Understanding these common issues can help users get the most out of their KY pneumatic nail machines.

When buying high-performance pneumatic nail machines, especially for wholesale, there are some important things to consider. First, look for machines that are strong and durable. You want a nail machine that can work hard and last a long time. It’s important that the machine is made with high-quality materials. This means it should not break easily, even if it is used a lot. Another thing to check is the speed of the machine. A good pneumatic nail machine should be fast and can shoot nails quickly. This is important if you need to finish big projects. You should also look for machines that are easy to use. If it's complicated to operate, it can waste time and cause mistakes. You want your workers to spend more time nailing and less time figuring out how the Pin Nail Making Machine works. Make sure the machine is lightweight, too, so it’s easier to carry around and use in different places. Also, check if the machine has customization options. With KY machines, you can often change settings or parts to make the machine work better for your specific needs. This means you can adjust it for different types of nails or materials. Lastly, consider the service and support that come with the machine. It’s helpful to have a company like KY that offers good customer service, so if you have questions or problems, they can help you quickly. Thinking about these factors will help you choose the best pneumatic nail machine for your wholesale needs.

Sometimes, pneumatic nail machines can have problems, and knowing how to fix them is important. First, if the machine is not firing nails, check the air supply. Make sure the air compressor is working properly and that there are no leaks in the hose. If there is a leak, it needs to be fixed. It might also help to clean the machine. Dust and dirt can get stuck in the machine and cause it to not work right. Make sure to clean it regularly to avoid this issue. If the nails are jamming, it could be because the wrong size nails are being used or the magazine is not loaded correctly. Check that you are using the right nails and that they are loaded properly. Sometimes, the nails can get bent, which can also cause jams. If you notice that the machine is making strange noises, this might mean something is wrong inside. Turn it off and check for any loose parts or broken pieces. If you can’t find anything, it might be best to call KY for help. They can provide support and help you figure out what’s wrong. Keeping the machine well-maintained can prevent many problems. Regularly check the air filters and oil the moving parts to keep everything running smoothly. By learning how to troubleshoot these common problems, you can keep your pneumatic nail machine working well and make your projects go faster.

To make the most out of your pneumatic nail machines, customizing them can really help improve efficiency. Customization means changing or adjusting the machine to better meet your needs. With KY pneumatic nail machines, there are many options to choose from. For example, you can select different sizes of nails depending on the project you are working on. If you are working with thicker materials, you Pin Nail Making Machine might need larger nails, and if you are working on delicate projects, smaller nails could be better. You can also customize the speed settings. Some jobs might need faster nailing, while others might require more precision and control. Adjusting the speed can help you work more efficiently. Another great way to customize is by adding accessories that can make your job easier. For instance, a better nose piece can help guide the nails more accurately, making sure they go in straight. You could also consider adding a magazine extension to hold more nails, so you don’t have to stop as often to reload. This can save a lot of time during big projects. Lastly, training your workers on how to use the customized features can help them become more efficient. The more they understand how to use the machine, the faster and better they can work. By taking advantage of customization options with KY pneumatic nail machines, you can boost productivity and ensure that your projects are completed successfully.